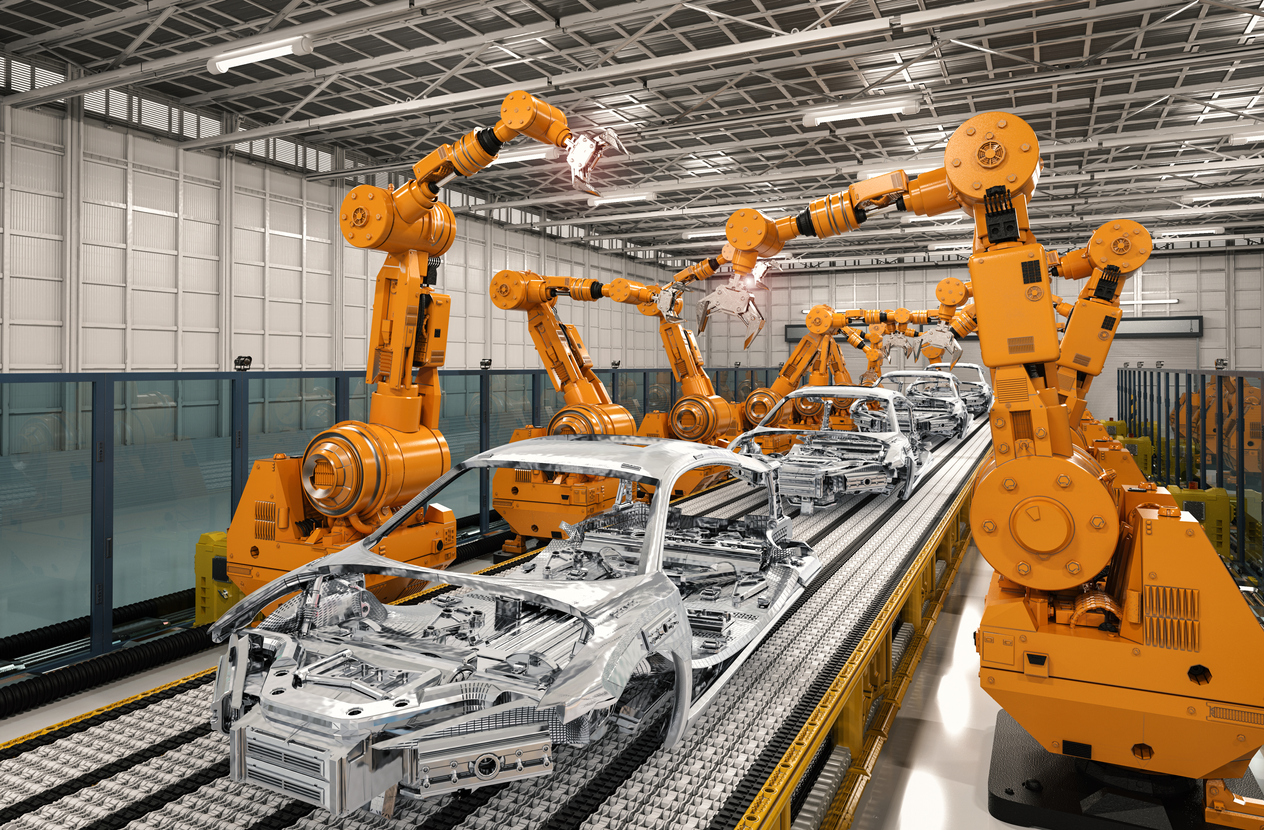

With Robots in manufacturing industries becoming popular day by day, they are changing the way we manufacture different objects. They are programmed to do a variety of tasks. From manufacturing smartphones to automobiles, they are used in manufacturing. Moreover, Robots are usually used to perform tasks that are often very high risk.

There are tasks that are unsuitable for human workers. With the use of Robots, this risk can be avoided. Therefore, Industrial Robots can improve a product’s quality dramatically. They can do the repeatable job with the most precision and control.

The level of reliability and focus on work in Robots have reached such a point which human beings just cannot. They really increase the safety of the workplace.

With the introduction of Collaborative Machines, the production rate of different products is increasing. We are reaching the ultimate level of technology. There are really cheap collaborative Robots available in the market. Collaborative Robots work with human beings. If a worker comes into the workplace, that robot will automatically stop.

Moreover, with the use of Robots in manufacturing industries, it is really possible to increase output with the maximum quality of products. In addition, Hiring Robots increases the speed, quality, and a number of products. Therefore, industries are hiring robots nowadays. There are a bunch of sensors that are in use for this purpose. It includes torque and tactile sensors.

Robotic Inspectors are also used. Moreover, they help in detecting various flaws in parts of objects that are being manufactured. Therefore, this increases the accuracy and overall quality of an object that is in the manufacturing stage. Manufacturing Robots are really cheap nowadays. Therefore it’s a really mind-blowing investment for various companies.

Advantages of Robots

Most people fall into the fear that robots will steal their jobs. Moreover, they think that at some point in the future, they will be unemployed. This is actually not the case. Rather than that, it’s the opposite. Robots are creating more job than what they are stealing actually. They provide too much good for companies. Fast-paced work done coupled with accuracy. It’s not like human jobs are gone.

Therefore, human workers are still needed to keep the machines up and running. So, really it’s just a win-win for both. Company and Employees, both benefit from the use of Robots. Many companies are trying to invest and set these Robots in manufacturing. Now let’s talk about some of the main advantages of Robots in Manufacturing industries.

1. Productivity

It’s not like Robots are the Machine Gods. Therefore, they cannot do anything you want them to do. Some things are just meant to be done by human workers. But the good thing is that Robots are actually really productive. Nowadays, they can literally do anything you want them to. From Answering Calls to sending E-Mails. The future is now.

Therefore, robots in the workplace can really minimize the burden on human employees. This is a win-win situation for both parties. Moreover, we are still afar from the next industrial revolution. I believe that with the passage of time, we will get to see more productivity in robots. Many Robots are currently used in various companies. With the right utilizing of them, it’s really one of the greatest innovations and asset for the company.

2. Creating Jobs

There is this myth that Robots are taking most jobs away. It’s actually not true. Robots are just changing the way job exists. They are not just straight up going to make us all unemployed. It’s never going to happen. Moreover, Robots do need the supervising of human beings. Not to mention they are monitored from time to time by human employees.

The more robots there are. Therefore, more engineers we need to make them. The more people we need to hire to supervise them.

It’s like this never-ending cycle of employments that is also created with the use of more and more robots. Companies, instead of firing the employees. They are training them. This builds a sense of good relationship with the employees.

Moreover, it also indicates that companies are not trying to fire you but they are actually changing the way you work in a certain position.

Moreover, there will be more and more opportunities for companies. With the increase in advancement every day, workers might be promoted. This is the ultimate change in the technology era.

3. Positive workers

Peace, love, and positivity are what robots in companies exert. They provide a really peaceful environment for a certain company. Robots are often assigned the work that is not particularly enjoyed by most workers. We human beings have the tendency to get bored pretty quickly

Since most of the tasks in building various products are repetitive, we get bored. Therefore, with the use of robots, there is not a word called “Bore” in the Robotic dictionary. With the use of robots, workers will be doing the stuff that is less nerve-wracking for them. They will participate in other stuff for making the company better.

This overall phenomenon will eventually upgrade everything that happens into that certain company. Finally, they will participate in innovating different stuff with their skills.

4. Consistency

Robots are not the type of things that will get bored attention taken. As a fellow human being, I myself have many attention issues. Sometimes it’s really hard to focus on what you’re doing. Therefore, this results in messing up the whole idea of working.

But, with robots, it’s all different. They do not have the ability to think like us. They don’t have mental health issues like us. Therefore, they don’t get distracted. This is one of the main advantages of using Robots in the workplace. The job of robots are inconsistent. They do one thing repeatedly. This is why most companies prefer robots doing their jobs instead of human beings. So, for sensitive tasks Robots are really essential. They are just doing what they are supposed to do. There is no in-between. Automation is much more reliable than human workers.

5. Speed and Accuracy

When it comes to speed and accuracy, Robots are straight-up fire. No human can beat them in this category. Unlike humans, Robots do not get bored or need breaks. They don’t ask for promotions or holidays. They do not even ask for vacation spending with their wife.

Robots do not even get tired. As long as you’re providing them with power, they are good to go. They do not feel exhausted and start doing things in a slow manner. Robots can work all the time with maximum speed and accuracy. They help the employees in having a good time at work. Therefore, this way no one has to actually work too much. They just create a really friendly environment.

In addition to speed comes accuracy. Robots perform very delicate tasks with ease. They can literally perform sensitive tasks with speed and precision. Delicate stuff can be easily done with the use of robots. Human being has shaky hands. So it’s really difficult to manage. With the use of robots, it’s not even big of a problem anymore.

6. Safety

With greater products comes a greater threat. Safety is the main advantage of using robots. Robots in manufacturing provide a sense of security to the company and the whole employees. By giving difficult and delicate tasks to robots, companies are avoiding most life-death situation threats.

Employees who work at a very dangerous site will have benefits from robots. They no longer have to make their life difficult by always getting into harder situations. Robots are there to assist them. Therefore, workers only have to assist robots to actually work. Heavy machinery that is made in hot temperatures with sharp objects can really injure humans. But with the use of Robotics, it’s not a problem anymore.

7. Precision and Perfection

Robots will always deliver the same sort of product. If they are made to build toys, they are always going to come up with the same design and the same precision. Moreover, they are programmed to do a repetitive and consistent task. So they always deliver the same quality.

Once a perfect design is chosen, a robot will always make the same perfect design for the company. Consistency and precision coupled with never stopping make it perfect for every company out there.

Types of Robots in Manufacturing

Let’s talk about the types of robots in the manufacturing industries. There are more than five types of robots that are used in the manufacturing industry. Let’s talk about them. These machines are classified according to their structures.

1 Cartesian Robots

Just as the name says, Cartesian Robots work the three Axis (X, Y, Z). With the help of three sliding joints, they move up and down motion. In addition to that, they can also be used in our motions.

These Cartesian Robots are one of the most commonly used robots. They are often used in 3D Printing. Down below is the link to one actuator if you’re interested in buying.

2. SCARA Robots

SCARA stands for “Selective Compliance Articulated Robot Arm“. It contains two joints that provide compliance and they have the ability to rotate. They are often used to assemble various products. The SCARA robots are really good for lateral movements. If you’re interested in buying, a link is down below.

3. Articulate Robots

These robots contain a lot of joints. From two to ten, the robot is connected to some base with a twisting joint in it. It looks just like a human’s arm. It’s mostly used in packaging and painting stuff. They are also used at pick and place applications as they provide really high speed with accuracy.

4. Delta Robots

These robots are heavily used in the manufacturing of food, medicines and electronic stuff. Moreover, they have a spider-like structure. Like all other robots, it’s also connected with a base. These are also used in pick and pack services due to high speeds and precision. As of now, they are not really available on Amazon but I will update the link if they are to sometime in the future.

5. Cylindrical Robots

It provides rotatory and rational movements. These robots are perfect for tight spaces. It has at least one rotatory joint. The applications include machine loading and unloading. It can also assemble various stuff.

Now let’s talk about the future of Robots in Manufacturing.

Future of Robots in Manufacturing

With the passage of time, Robots have really changed a whole lot. In the previous era, they were known for working. But nowadays robots are much more. They are a perfect mix of Artificial Intelligence and Power. These two circumstances occurring together make up a robot.

Today, robots can be really integrated into workplaces. In the past, robots were meant to do one thing just lying in one place. On the other hand, nowadays robots can move freely as they please and they can do a whole lot of stuff altogether. The Collaborative robots we talked about earlier help a lot of workers by assisting them. It’s not an easy job to do. The sensors enable them to work in a human-friendly environment. As a result, in addition to great products, a thorough analysis is also done with the use of Collaborative robots.

Advancements in Robots have made us step up the game of everything. From making floors to smartphones, robots are practically everywhere. Autonomous has already taken over many grocery stores. With the use of some sensors and a camera, it’s possible to achieve anything.

In other industries such as agriculture, drones are in work to find and analyze various data. Like, deficiency of a certain thing in crops. They can also analyze the water and dryness levels of the ground. Robots in Manufacturing are providing a great chance for our industry to grow. It will grow on a big scale.

How are Robots used in Manufacturing Industries?

Since the inception of robots in 1954, they have been doing a lot of stuff. And I’m talking about manufacturing industries. From die casting to spot fielding, Robots have actually served us well. Moreover, they are still serving us on this date. Robots have taken over our industries. Instead of taking ways jobs, they’ve created more jobs too. There are a ton of things that a robot can do.

It’s pretty safe to say that robots are reshaping the whole manufacturing industry. Now, let’s talk about some of the main manufacturing applications and how Robots are used in the manufacturing industry.

1. Assembly Lines

One of the main significances of having a robot at your workplace is that they minimize manufacturing waste, unlike human beings. Robots use something called the “Lean Manufacturing” assembly. An automated assembly line is really essential for our robot manufacturing industry. It’s because it can do a variety of stuff from manufacturing food to automation.

Robots are actually to some sort, eco-friendly. They don’t waste. Rather than that, they reduce waste materials. With the change in technology with the passage of time, I’m positive that it’ll even impact the industry more than what it’s doing right now. Robots can change our environment. They can change jobs for humans, who have to do assembly line tiring jobs.

2. Pick and Pack

With speed and precision as it’s a trait, robots can do picking and packing. Picking and packing job requires persistence, consistency, power, and speed. Robots are becoming more and more with the passage of time. Moreover, pick and pack jobs can really impact a person’s health. It can also decrease the speed and consistency of human workers working.

Therefore, Pick and Pack Robots are actually really productive and they don’t get tired. Unlike a human, they will straight off do what they are supposed too. This is also the reason why pick and pack robots are actually pretty popular in our manufacturing industries right now.

3. Arc Welding

Even saw those steel-producing robots? Arc Welding is the most common type of robot that are used in Automobile and Steel production companies. Co-working with humans and helping them to achieve it. Human workers prepare the parts and then these robots join them. They can do their job with more speed, efficiency, and persistence than human workers.

Wielding is the process in which a large amount of heat is applied to connect to pieces of metal. This involves a whole lot of risk for human workers. So, with the use of these robots, it’s pretty easy to avoid health risk for a worker. This is the main significance of these robots. Robots, replacing humans avoid this whole mess.

More Applications

Pick and Pack, Wielding and assembly lines are the most common types of applications of Robots in the Manufacturing industry. In addition to that, robots are used in even other industries. For example, anti-contamination robots often are used in cleaning jobs that are used in an isolated environment. There are some other applications too. They are as follows

- Automotive

- Aerospace

- Electronics

- Food

- Textile

- Mining and Drilling

These are some other applications of Robots in the manufacturing industry. They are used from Robots in car manufacturing industries to so on. With these advantages, there are some disadvantages of using Robots in Manufacturing industry too. Keeping them in mind, let’s talk about some of the disadvantages.

Disadvantages of Robots

1. Investment Costs

When Robots are invested in a new company, the investment cost is high for them. This is the biggest step that a company takes. Whether to invest in robots or not. The starting cost can be a lot for a company. But, with the passage of time, robots can pay back the investments made on them. This is the biggest benefit of using robots in organizations.

2. Staff

With the use of robots, companies also need to deal with them. For this purpose, they have two choices. Whether to train the existing staff or to hire skilled staff. The implementation of Robots opens a whole new dimension of technology. Most workers actually won’t get programming and stuff as they are hired to do their own work. So sometimes it can be stressful for existing workers to work on them

This is why the new staff is hired. In addition to that, it causes a lot of money for a company to hire new staff.

3. Job Losses

Now, it’s not like robots are stealing all the jobs. But, I’d like to mention that to some degree, it’s safe to that that they are stealing jobs. The person who was making a certain product isn’t making it now. Robots have already taken over it. As robots in the manufacturing industry can perform a lot of things with precision and accuracy, they are preferred. While job loss myth is true to some degree, it isn’t actually a hundred percent true.

Human beings still continue to play a vital role in manufacturing industries. They still have to operate the same robot that has taken over their job. Amazon is a great example actually.

Final Word

Keeping everything in mind, Robot in manufacturing industry plays a vital role. From making a simple product to complex cars. We see robots practically everywhere. Robots will make our industry faster and better than it is right now. They still are serving us day by day. In the future, I hope to see an even bigger evolution in the world of automation robots.

There are advantages and disadvantages to using robots in manufacturing industries. But in my opinion, the advantages far exceed the actual cons of them. So it’s pretty safe to assume that robots are serving and doing much better than harm. Machines and Automation is the future. We will see an even bigger industrial revolution in our world. That will be the rise of Robots everywhere. Imagine a workplace with Artificial Intelligent robots in manufacturing industries. That time is not that far actually.